Plastics professionals benefit from Penn College workshop

Published 06.01.2023

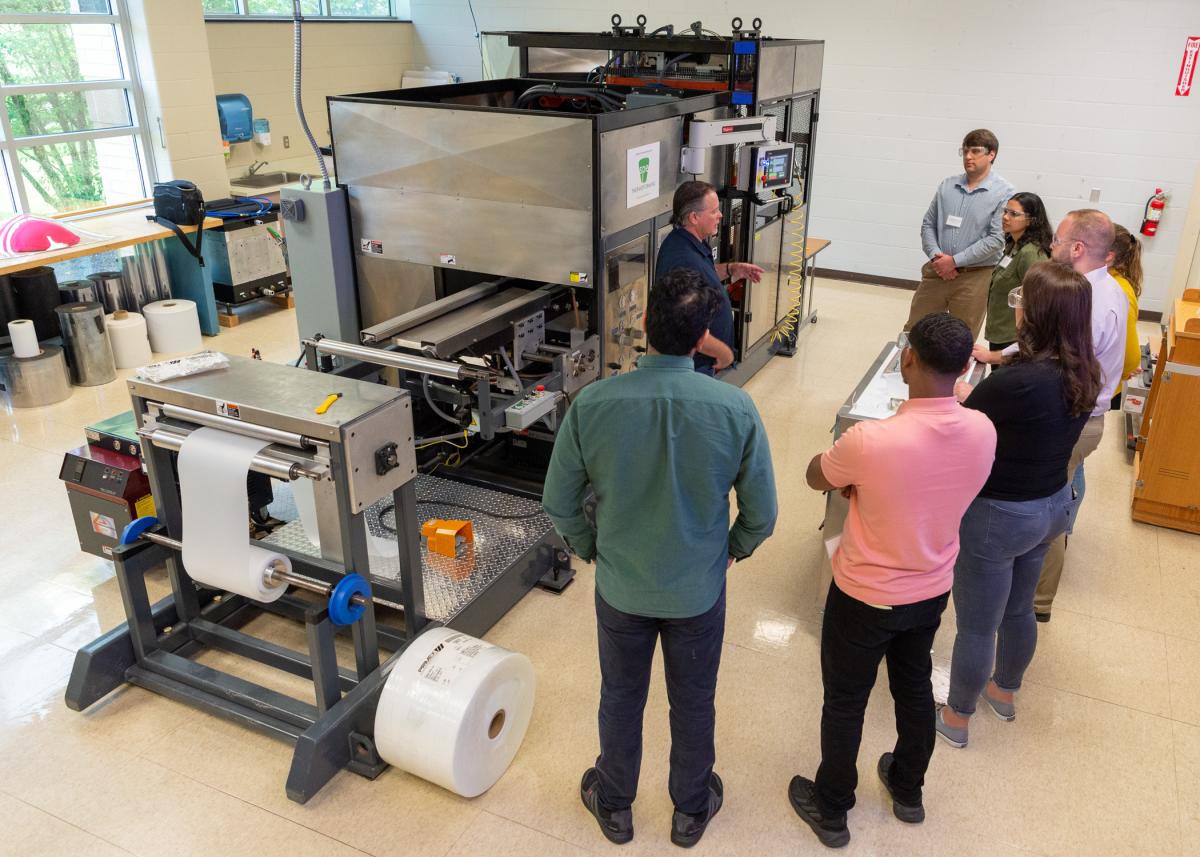

Fifteen employees from six companies benefited from instructional material and hands-on reinforcement during the recent Plastic Materials & Processing Fundamentals workshop at Pennsylvania College of Technology.

The May 23-25 workshop, sponsored by the Mitsubishi Chemical Group, is among a series of development opportunities for industry professionals offered throughout the summer in the college’s renowned Plastics Innovation & Resource Center.

Attendees covered the basics of polymer structure, and lab sessions showed how certain properties – melt index, tensile strength and impact resistance, for instance – are determined. Coursework also introduced the five major processes: injection molding, extrusion, rotational molding, thermoforming and blow molding.

Vii J. Rice, plastics technology faculty/department head, was the lead instructor, joined in the injection molding lab by instructor Mark A. Sneidman; in the blow molding lab by instructor Jose M. Perez Jr.; and in the rotational molding and thermoforming labs by Christopher J. Gagliano, PIRC project manager. Nathan A. Rader-Edkin, PIRC program manager, also assisted in the workshop.

Five registrants represented Autoneum North America Inc., Bloomsburg; three each are employed by Airlite Plastics Co., Nazareth, and by ExxonMobil Product Solutions Co., Baytown, Texas; two were from Sekisui Kydex LLC, Bloomsburg; and one each traveled to campus from iNOEX Inc., Lancaster, and Teleflex Inc., Reading.

“This course is great for a broad spectrum of professionals in the plastics industry,” said Ryan Varney, production manager for Airlite Plastics Co. “Engineers, managers and supervisors would all benefit.”

“Attending this workshop provided me with an incredible insight into the plastics industry. As a marketing professional, I wanted to understand more about plastics to guide me in marketing not only our product, but the plastics manufacturing industry itself,” added Sekisui Kydex LLC’s Nicole Rauch. “Without this workshop, I wouldn’t possess all the ‘behind the scenes’ knowledge I now have.”

“The Plastic Materials & Processing Fundamentals workshop enhanced both my scientific and technical knowledge of plastic materials,” said Lindsey Duque, an ExxonMobil Product Solutions Co. research and technology specialist. “This will help with my project management and assisting the lab technicians in their daily assignments.”

To learn more about the PIRC, among the leading centers in the country for plastics research, development and education, call 570-321-5533.

Penn College is one of six institutions nationwide offering plastics degrees – a bachelor’s in plastics & polymer engineering technology and an associate degree in plastics & polymer technology – that are accredited by the Engineering Technology Accreditation Commission of ABET.

For more about the college, a national leader in applied technology education, email the Admissions Office or call toll-free 800-367-9222.