Metal Fabrication Technology

About this program

Tomorrow needs skilled workers with technical know-how. When you define your future at Penn College, you'll take on the exact skills that employers want most. This industry-driven program delivers competitive-edge training in welding, machining, and sheet metal fabrication. Small class sizes. Strong industry connections. And opportunities to earn dual degrees in related areas take career prospects to even greater heights!

Next steps...

You're on your way to becoming a tomorrow maker.

20+

Hours Per Week of Hands-on Time in Labs

Earn Industry Certifications

Master Welding, Machining, & Sheet Metal Processes

Careers

- Metal fabricator

- Production technician

- Assembler

Courses

At Penn College, we believe your educational experience should go beyond specialized skills. Real-world ready means taking a broader approach that builds communication skills, inspires collaboration, and encourages exploration of arts, history, and science.

Specialization requires in-depth knowledge and high-level proficiency. Students learn and apply major-specific concepts, skills, and methods.

- MTT128Mill Applications

- MTT129Lathe Applications

- WEL102Welding Blueprint & Layout

- WEL103Welding for NDT I

- WEL104Welding for NDT II

- WEL240Basic CNC Programming

- MTT213Machine Tool Applications

- MTT222Fixture Design & Fabrication

- WEL252Welding Blueprint & Layout II

- MTT130Sheet Metal Forming & Fabrication

- MTT216Abrasive Machining & Heat Treatment

- MSC106Introduction to Metallurgy

- QAL241Non-Destructive Testing I

- PERELCElective Courses - 3 Credits Required

Perspectives are points of view, offering a variety of ways of understanding, interacting, and influencing the world. Students identify, explain, and utilize the approaches used by academics and professionals to study, analyze, or understand problems, and offer solutions.

Tour Schedule

Seeing is believing.

Think Penn College might be a good fit for you? Make plans to visit and discover what hands-on learning is all about.

Hands-on Learning

Student Projects

Nate Filion, Metal Fabrication Technology, makes a cup holder for his 1953 Ford F100.

Hands-on Learning

Student Projects

Josh Safko, Metal Fabrication Technology, works to repair the gas tank of his motorcycle.

Hands-on Learning

Student Projects

Riley Cotner, Engineering Design Technology, and Jesse Rush, Welding & Fabrication Engineering Technology & Metal Fabrication Technology, collaborate to turn bomber seats into bar stools.

Hands-on Learning

Student Projects

Zachary King, Welding & Fabrication Engineering Technology, works on a ¼ scale Jaguar XK rear fender.

Hands-one Learning

Student Projects

Dan Gerard, Automated Manufacturing Technology, works on the sheet metal body parts for a front engine dragster, which will eventually compete in races.

Hands-on Learning

Student Projects

Trevor North, Welding & Fabrication Engineering Technology, works to replace a quarter panel for an Austin Healey Sprite.

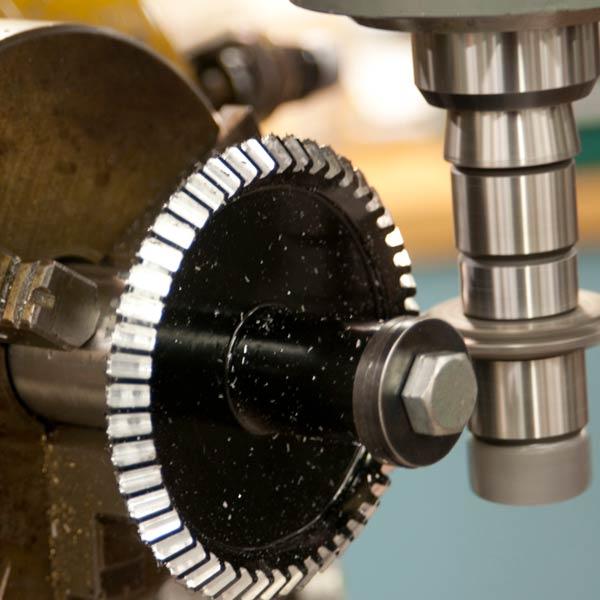

Facilities

Larry A. Ward Machining Technologies Center

Get hands-on experience in our specialized, newly renovated labs using industry-standard equipment just like you’ll see in the real world.

Student Experience

“The way we learn, we have lecture for 45 minutes to an hour a day, then we get out in the shop and are out there for three or four hours, or even more if we want to stay later. ”

Kevin McGinty

METAL FABRICATION TECHNOLOGY

Internship

Your knowledge in practice

Internships are key for career preparation. Apply your knowledge to the workplace and learn about the industry first-hand.

Related Programs

Follow your passion

Student Life

Lead and put your skills to the test

Baja SAE

Join other students, across various majors, and apply your skills to design a vehicle to compete in regular Baja SAE competitions.

American Welding Society (AWS)

Work together as a team on club projects and gain exposure to the welding industry through tours of local and regional businesses.

Student Organizations at Penn College

Your college experience is about more than the classroom. Join one of 65+ clubs and organizations, or create your own.

Penn College News

Tuesday, February 10, 2026

Collaboration benefits Penn College automation students

Study Abroad

Gain global experience

See the world via Williamsport. Take your education abroad and get hands-on experience learning about your industry on a global scale.

Student Experience

The community as their classroom

Living Outside 'You'

George Settle III trekked to the Middle East, bound for the Home of Hope, where he hoped to teach welding skills to a few of the children living there – many used, abused or abandoned, picked up by police from the streets of Beirut. In the process, the children taught him.

More Information

The machining course work in this associate degree is included in the Accredited Testing/Certification Institute for the National Institute for Metalworking Skills (NIMS). This accreditation enables our certified faculty to offer NIMS certification exams to our students or to award alternative credit to those students who have already successfully completed certification exams.

This major is subject to the transfer standards established by the College (see http://www.pct.edu/catalog/TransferringCredits ). Exceptions must be approved by the school dean

Alternative Credit refers to academic credits earned through means other than traditional college course completion, including: credit by exam, articulation, proof of competency gained in high school, work/life experience, and advanced placement.

Visit the Alternative Credit Options page for requirements and procedures and for information on credit through Advanced Placement.

The first two semesters of the program focus on machining courses. It is recommended that students review the Automated Manufacturing & Machining Required Tools list to determine what tools and supplies they will need to purchase for this phase of the major.

The final two semesters of the program focus on welding courses. It is recommended that students review the Welding Tools & Supplies list to determine what tools and supplies they will need to purchase for this phase of the major.

Personal Protection Equipment and tools are available for purchase through The College Store .

- Mr. Dan Bechek, Sales Engineer / Central PA, Lincoln Electric

- Mr. Robert Blauser, '96, '00, Vice President of Operations, GSM Industrial

- Mr. Richard A Conrad, Jr., '02, Field Application Engineer, Hobart/Miller Electric

- Mr. Jacob D Fisher, '10, Plant Manager, High Steel Structures LLC.

- Mr. Eric F Geier, '17, Operations Leadership Rotation Future Leader, Aerojet Rocketdyne

- Mr. Matthew Hillyer, Welding Engineer, Johnson Controls Navy Systems

- Mr. Michael Sebergandio, '01, '03, Quality Engineer - Welding, Case New Holland

- Mr. Brian A Thompson, Owner, Jasper Steel Works, LLC

- Mr. Richard Wagoner, Principal Construction Training Leader, UGI Utilities