Penn College offers pathways for aspiring NDT inspectors

Published 01.08.2024

Pennsylvania College of Technology is providing career pathways for individuals who wish to safeguard critical aspects of society. The college is offering an associate degree and competency credentials in non-destructive testing.

“When we started this program, we had numerous companies come and say, ‘We will hire everyone who graduates from this program. We’re just desperate for trained NDT inspectors,’” recalled Bradley M. Webb, dean of engineering technologies.

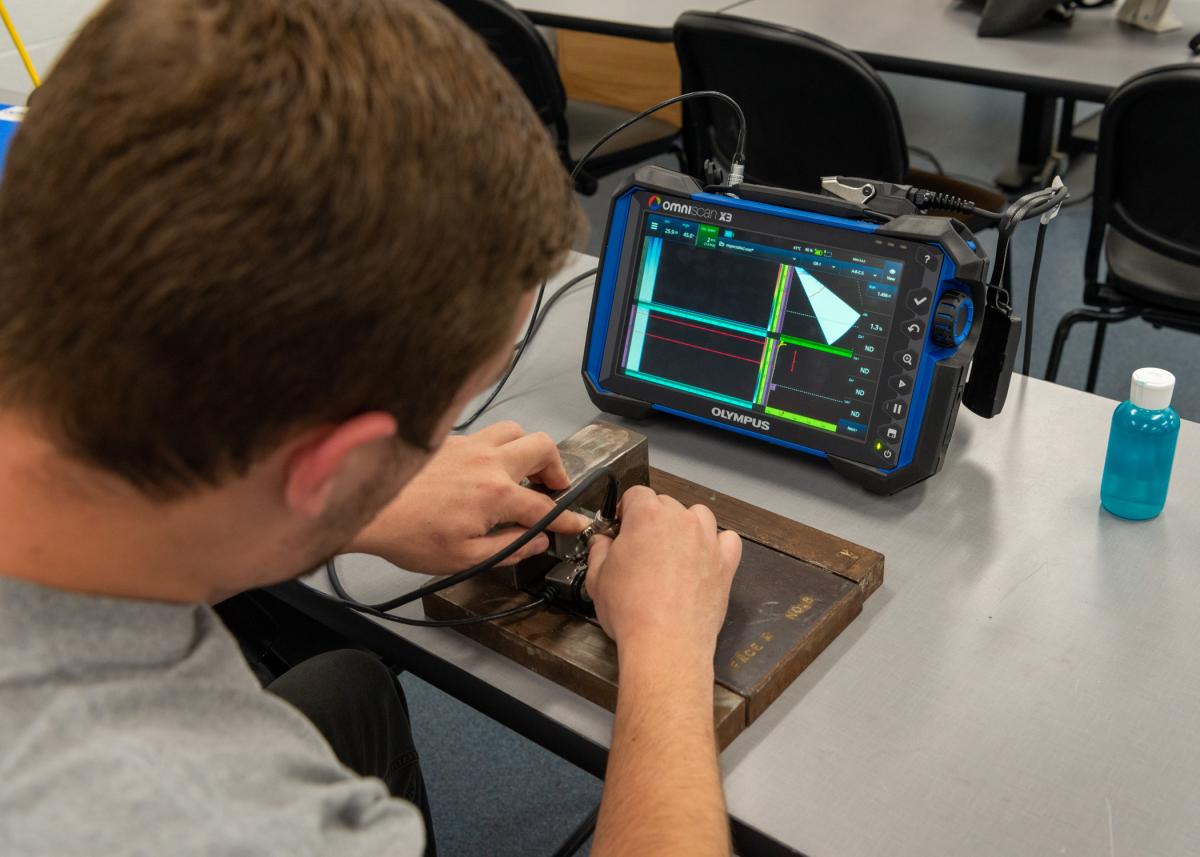

As shown in a recent Penn College video, non-destructive testing, or NDT, refers to several noninvasive technologies employed to test the integrity of parts, components and assemblies in structures, machinery and vessels. NDT professionals help prevent injury or loss of life by ensuring that essential industries – including manufacturing, construction, transportation, oil and gas, and aviation – meet quality and safety assurance requirements.

“There’re billions of dollars of work that needs to be inspected. But there just are not enough people who have that skill,” Webb said.

While it has offered some NDT classes since the mid-1980s, Penn College began the NDT associate degree major in Fall 2022. The initiative was part of a three-year, $599,816 National Science Foundation grant devoted to advanced technology education in fields that drive the economy (NSF Award 2000831).

The college purchased industry-standard equipment to enhance practical experience for students in a variety of NDT processes: radiographic, ultrasonic, phased-array ultrasonic, magnetic particle, liquid penetrant and visual inspection.

“Our degree is unique in that we’re giving students hours of training. They know how to use the equipment. They know how to inspect parts and accept and reject parts,” said Michael J. Nau, a welding instructor and former Level II radiographic NDT inspector. Nau and James N. Colton II, assistant professor of welding, developed the NDT curriculum.

The NDT degree is intertwined with Penn College’s welding program. NDT students learn welding basics in the college’s 55,000-square-foot lab before using their NDT skills to test the work produced by welding majors.

“NDT and welding go hand-in-hand. Most every weld that’s put down – by code – has to be inspected. So that’s where our niche is,” Nau explained. “Our students can inspect welds visually and with non-destructive testing.”

Zach A. Snyder, of Kintnersville, and Madison T. Holland, of Montoursville, are two of several students who are combining the NDT associate degree with a bachelor’s degree (welding & fabrication engineering technology for Snyder and applied management for Holland).

“NDT is just fascinating to me. Getting to do radiation work and this UT (ultrasonic) work, we get an in-depth view of what’s going on inside that weld,” Snyder said. “It’s no longer, ‘Oh, it looks good on the outside.’ I know what’s happening inside.”

“I love how we have hands-on experience with the welding students,” Holland added. “We give practical examinations to the students, and then we test their plates. And we send it back to them like a real welding exam, so it gives us some experience for the field.”

Graduates of the NDT associate degree earn essential classroom hours toward American Society of Non-Destructive Testing certification in both radiographic and ultrasonic testing, the two most common NDT procedures. The college also offers a one-semester competency credential for either method. ASNT certification is achieved following on-the-job training.

“Depending on whether you want to work out in the field traveling (for an inspection company) or whether you want to work in-house somewhere, there are two different avenues you can take,” Nau said.

Williamsport-based Lycoming Engines – the manufacturer of piston engines that power more than half of the world’s general aviation fleet, both rotary and fixed-wing – employs several in-house NDT inspectors.

“We must ensure quality is ‘built in’ from the purchased raw materials through our fabrication and assembly, up to and including testing the engine and conducting post-validation inspections,” said Shannon Massey, senior vice president for Lycoming Engines. “We build every engine as if we were flying it ourselves and a critical function of ensuring that are the multiple non-destructive testing and inspections that are completed to guarantee our products meet our standard for the safe flight of others.”

Over 30% of Lycoming Engines’ workforce consists of Penn College graduates, a fact Massey credits to the company’s diverse technical needs aligning with the school’s commitment to applied technology education. She anticipates NDT graduates will be the latest example of the strong relationship between the two entities.

“We were beyond ecstatic when PCT added the NDT associate degree. That provides an avenue not only for our workforce but across industries that are looking for this,” Massey said. “Right now, if I had an individual asking, ‘What’s a degree path that I know I’m not going to have to worry about having offers when I graduate?’ NDT is absolutely one of those degree programs that you want to look into.”

Holland is following that advice. Her goal is to become a Level II inspector in either ultrasonic or radiographic testing.

“NDT needs a lot of workers. It’s a good environment to be in when you get older. It’s not a back-breaking kind of job, but it’s still very fun. You still get to deal with all the different welding processes,” she said.

Snyder is also looking long term.

“I love welding. It’s what I always wanted to do, but at some point, it’s nice to have a secondary skill set,” he said. “If I decide I want to go into more of the quality control and inspection side of things, I have that versatility, which I really find valuable.”

According to the Bureau of Labor Statistics, the median annual salary for NDT technicians is about $65,500.

“We have room for more students in the NDT program, and I think Penn College is a great place to experience NDT,” Webb said. “We have the technology, and we have the experts. Our faculty (Nau and Mark N. Hurd) were Level II inspectors in industry. They’ve been there, they’ve done it. We’re constantly reinvesting in our program and our students to make sure that we’re producing what industry needs.”

For more information on NDT and other degrees offered by Penn College’s School of Engineering Technologies, call 570-327-4520.

Penn College is a national leader in applied technology education. Email the Admissions Office or call toll-free 800-367-9222.