Penn College Plastics Students Recognized for Research

Wednesday, October 15, 2014

Research conducted by plastics and polymer engineering technology majors at Pennsylvania College of Technology has been recognized by the Rotational Molding Division of the Society of Plastics Engineers.

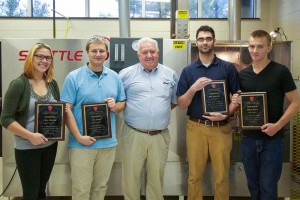

Larry Schneider, representing the board of directors of the SPE Rotational Molding Division, recently commemorated the students’ work by traveling to campus and presenting plaques to Julia I. Gilchrist, of Hanover; Thomas J. Ryder, of Muncy; Benjamin G. Robertson, of Hummelstown; and Taylor J. Smith, of Williamsport.

The four students researched powdered polyethylene and micro-pelletized polyethylene. Earlier this year, Gilchrist and Ryder delivered the team’s findings in Cleveland at RMD TOPCON, a forum for SPE members to exchange information regarding rotational molding.

“It’s quite appropriate that these four students have been recognized for their commitment to the plastics field,” said David R. Cotner, dean of the School of Industrial, Computing & Engineering Technologies. “Their hard work in conducting the study is a great example of how students can enhance their education outside of regular class and lab sessions. Presenting their research at a well-respected industry event speaks to the quality of their work.”

In rotational molding, plastic is melted inside a hollow mold that is machined to the shape and size of the desired plastic part. The students researched which type of plastic, polyethylene powder or micro polyethylene pellets performs best in terms of flowing into difficult features and minimizing voids in the rotational molding process. They concluded that the pellets were superior and recommended additional study.

In rotational molding, plastic is melted inside a hollow mold that is machined to the shape and size of the desired plastic part. The students researched which type of plastic, polyethylene powder or micro polyethylene pellets performs best in terms of flowing into difficult features and minimizing voids in the rotational molding process. They concluded that the pellets were superior and recommended additional study.

The students conducted their research at Penn College’s Rotational Molding Center of Excellence. Part of the Plastics Innovation & Resource Center, the Rotational Molding Center of Excellence offers independent, hands-on applied research and development to the rotomolding community.

Gary E. McQuay, PIRC engineering manager, attended RMD TOPCON with Gilchrist and Ryder and was impressed with the duo’s presentation.

“Both Julia and Tom were very professional and respectful and made a lot of friends at the conference,” he said. “They were excellent ambassadors for Penn College, the plastics department and the PIRC.”

Penn College is one of only five plastics programs in the nation offering degrees accredited by the Engineering Technology Accreditation Commission of ABET. For information on the plastics degrees and other majors offered by the School of Industrial, Computing & Engineering Technologies, call 570-327-4520.

The PIRC is one of the top plastics technology centers in the nation for research development and education related to injection molding, extrusion, blow molding, rotational molding and thermoforming. To learn more about the PIRC and the Rotational Molding Center of Excellence, call 570-321-5533.

For more about Penn College, which is celebrating its Centennial throughout 2014, email the Admissions Office or call toll-free 800-367-9222.

Larry Schneider, representing the board of directors of the SPE Rotational Molding Division, recently commemorated the students’ work by traveling to campus and presenting plaques to Julia I. Gilchrist, of Hanover; Thomas J. Ryder, of Muncy; Benjamin G. Robertson, of Hummelstown; and Taylor J. Smith, of Williamsport.

The four students researched powdered polyethylene and micro-pelletized polyethylene. Earlier this year, Gilchrist and Ryder delivered the team’s findings in Cleveland at RMD TOPCON, a forum for SPE members to exchange information regarding rotational molding.

“It’s quite appropriate that these four students have been recognized for their commitment to the plastics field,” said David R. Cotner, dean of the School of Industrial, Computing & Engineering Technologies. “Their hard work in conducting the study is a great example of how students can enhance their education outside of regular class and lab sessions. Presenting their research at a well-respected industry event speaks to the quality of their work.”

In rotational molding, plastic is melted inside a hollow mold that is machined to the shape and size of the desired plastic part. The students researched which type of plastic, polyethylene powder or micro polyethylene pellets performs best in terms of flowing into difficult features and minimizing voids in the rotational molding process. They concluded that the pellets were superior and recommended additional study.

In rotational molding, plastic is melted inside a hollow mold that is machined to the shape and size of the desired plastic part. The students researched which type of plastic, polyethylene powder or micro polyethylene pellets performs best in terms of flowing into difficult features and minimizing voids in the rotational molding process. They concluded that the pellets were superior and recommended additional study.The students conducted their research at Penn College’s Rotational Molding Center of Excellence. Part of the Plastics Innovation & Resource Center, the Rotational Molding Center of Excellence offers independent, hands-on applied research and development to the rotomolding community.

Gary E. McQuay, PIRC engineering manager, attended RMD TOPCON with Gilchrist and Ryder and was impressed with the duo’s presentation.

“Both Julia and Tom were very professional and respectful and made a lot of friends at the conference,” he said. “They were excellent ambassadors for Penn College, the plastics department and the PIRC.”

Penn College is one of only five plastics programs in the nation offering degrees accredited by the Engineering Technology Accreditation Commission of ABET. For information on the plastics degrees and other majors offered by the School of Industrial, Computing & Engineering Technologies, call 570-327-4520.

The PIRC is one of the top plastics technology centers in the nation for research development and education related to injection molding, extrusion, blow molding, rotational molding and thermoforming. To learn more about the PIRC and the Rotational Molding Center of Excellence, call 570-321-5533.

For more about Penn College, which is celebrating its Centennial throughout 2014, email the Admissions Office or call toll-free 800-367-9222.