Pennsylvania College of Technology “manufactured” an enriching educational adventure for students this summer with a 16-day excursion to Germany and an institution renowned for vocational training.

Led by Richard K. Hendricks Jr. and Howard W. Troup, instructors of automated manufacturing and machining, the seven students experienced a mix of classroom, lab and hands-on work with German machining methods. The three-credit course – Precision Machining in Germany – comprised robotics, CNC and PLC programming, quality control specialist training, and tours of leading companies reflecting Industry 4.0, manufacturing’s increasing reliance on smart automation and data exchange.

Company visits included Haimer Inc., high-precision products for metal cutting; Kuka Robotics, industrial robots and systems; Voith Hydro, hydroelectric power turbine systems; and Porsche, high-performance sports cars.

Company visits included Haimer Inc., high-precision products for metal cutting; Kuka Robotics, industrial robots and systems; Voith Hydro, hydroelectric power turbine systems; and Porsche, high-performance sports cars.

“Students were able to witness in-house examples of what makes Germany one of the world’s leaders in advanced manufacturing and automation,” Hendricks said about the trip, coordinated with Eckert Schools International. “We were the first U.S. school to partner with Eckert and secure them as a host.”

Eckert, based in Regenstauf, is known worldwide for providing professional education and expertise regarding the highest “Made in Germany” quality standards. It plays a key role in the nation’s dual-enrollment program, which encourages high school students to combine academic study with company and vocational training.

“One of the goals was for our students to see the effectiveness of the German educational system and compare it to our career and technical education model,” Hendricks said.

The comparison made quite an impression on at least one student.

“The biggest difference between programs in the United States and Germany is the depth of employer involvement,” said Dakota C. Harrison, of Lewisberry, who aspires to own a manufacturing company. “For my facility, I would develop an apprenticeship program like the German model so students would learn in a real manufacturing environment along with their schooling, blurring the lines between education and employment. If this model was more widely used in the United States, I believe it would allow companies to be more successful in developing a workforce.”

A study by Deloitte and The Manufacturing Institute estimates there will be 2.1 million unfilled U.S. manufacturing jobs by 2030.

In 2019, the National Science Foundation aided Penn College’s efforts to shrink the skills gap by awarding a $591,924 grant. A supplement to that grant funded the trip to Germany.

The Penn College contingent included two recent graduates: Harrison and Caleb J. Harvey, of Pittsgrove, New Jersey. Both students earned a bachelor’s degree in manufacturing engineering technology and an associate degree in automated manufacturing technology. Harvey obtained an additional associate degree in machine tool technology.

They were joined by current manufacturing engineering technology students Trevor L. Keaton, of Lansdale; Jacob T. Martin, of Williamsport; Shelby N. Miller, of Schuylkill Haven; Jay Patel, of Canton, Michigan; and Baldomero A. Silva, of Kennesaw, Georgia. Keaton, Martin, Patel and Silva are also seeking associate degrees in automated manufacturing technology and machine tool technology while Miller aims to add an associate degree in metal fabrication technology.

Inspired by their experience, Martin and Harrison devised a special project for the crew and their German hosts – a commemorative aluminum plate featuring the Penn College Wildcat and Eckert’s logo, gear teeth, separated by an inscription noting the year, the names of the schools and the statement: “Knowledge is power.”

“Jacob brought up how it would be cool to leave with something, and what started as a simple idea quickly evolved. We wanted a tangible representation of the skills within our group and the Eckert faculty. The plaque would represent both schools’ pride in hands-on manufacturing,” Harrison explained.

The duo primarily focused on the logos while Peter Zollner, manager of Eckert’s Metal Trades Department, collaborated with the other students on the remaining facets of the design.

“It was actually more of a challenge than we had anticipated,” Harrison admitted.

The file containing the Wildcat mark wasn’t compatible with ShopMill, the programming system for the CNC milling machine required to engrave the plaque. To use the logo, Harrison and Miller had to redraw it in AutoCAD. The challenging aspect? All the commands in the computer-aided design and drafting software were in German.

“We stuck with it, which in the end, made the project much more memorable. We literally broke the language barrier to bring our logo into reality,” Harrison said. “The design was simple yet well-manufactured. I even learned a new style of engraving tool, which did an excellent job with the fine features we drew.”

“Taking the initiative to produce a commemorative plaque in the middle of a full and unique global experience is yet another example of what sets Penn College students apart and why our manufacturing graduates are in such high demand,” said Bradley M. Webb, dean of engineering technologies. “It was the perfect capstone to a valuable educational and cultural experience that we hope will be offered again.”

If so, future students will not be disappointed, judging from Harrison’s reaction.

“It was quite an amazing experience. I could not have asked for a better way to finish my time at Penn College,” he said.

For information about the college’s manufacturing majors and other programs offered by the School of Engineering Technologies, call 570-327-4520.

Penn College is a national leader in applied technology education. Email the Admissions Office or call toll-free 800-367-9222.

– Photos provided by Eckert Schools International

Harrison (left) and Miller proudly display the product sparked by their imagination …

The collaborative aluminum plate begins to take shape.

The smiles of Lei, Zollner, Troup, Hendricks and Saule (from left) reflect the strong connection forged between the two institutions.

... that commemorates the partnership between Penn College and Eckert Schools International.

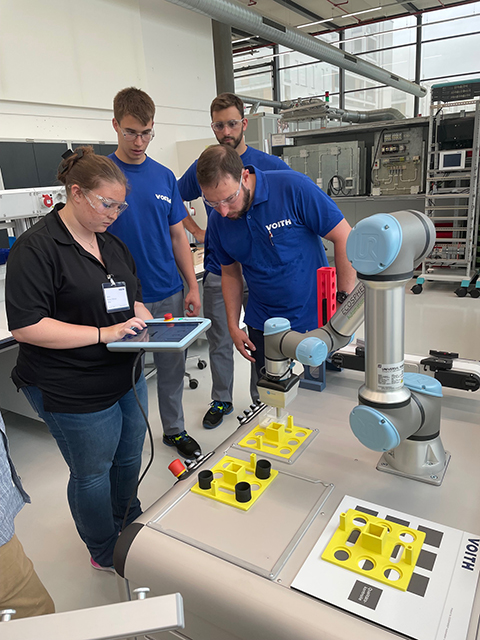

Miller operates a robot at Voith Hydro’s training center ...

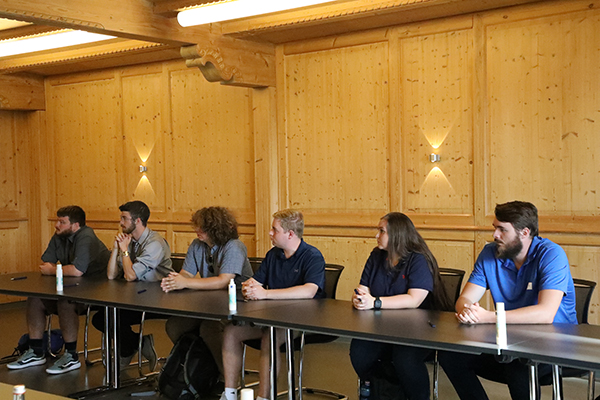

Harvey, Harrison, Silva, Keaton, Miller and Martin (from left) listen intently during a classroom session.

The Penn College students strike a pose in front of a hydroelectric turbine blade during a tour of Voith Hydro in Heidenheim, Germany. Voith Hydro is a leading producer of hydroelectric power turbine systems.

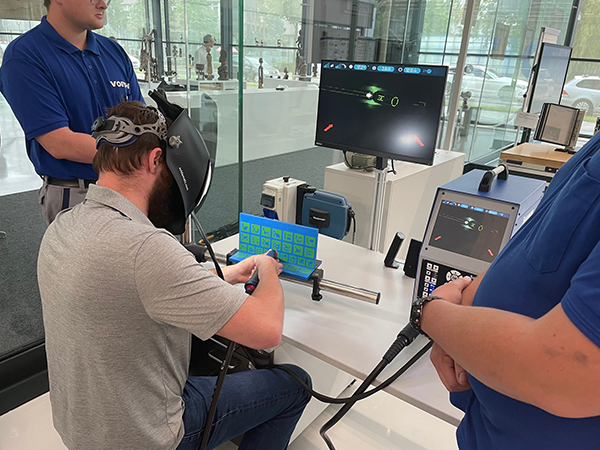

... while Martin tests his skills with a welding simulator.